Lasers for interference lithography

Stable, single frequency DPSS lasers engineered for large area, high contrast nanoscale patterning

Interference lithography relies on precise, stable laser light to create periodic nanostructures with high spatial frequency and uniformity. Skylark NX single frequency DPSS lasers at 320 nm and 349 nm deliver the coherence, beam quality, and wavelength stability required for high-throughput, defect-free patterning on resists and substrates.

320 nm

up to 200 mW

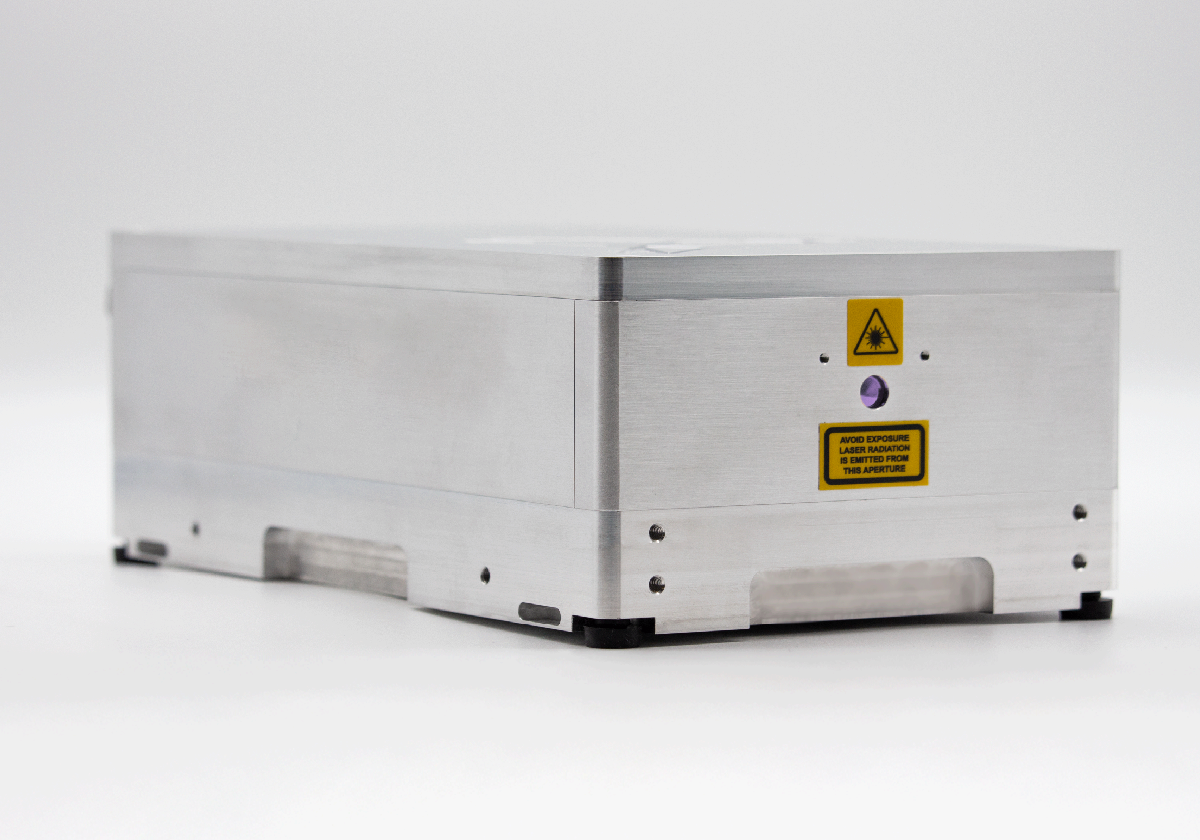

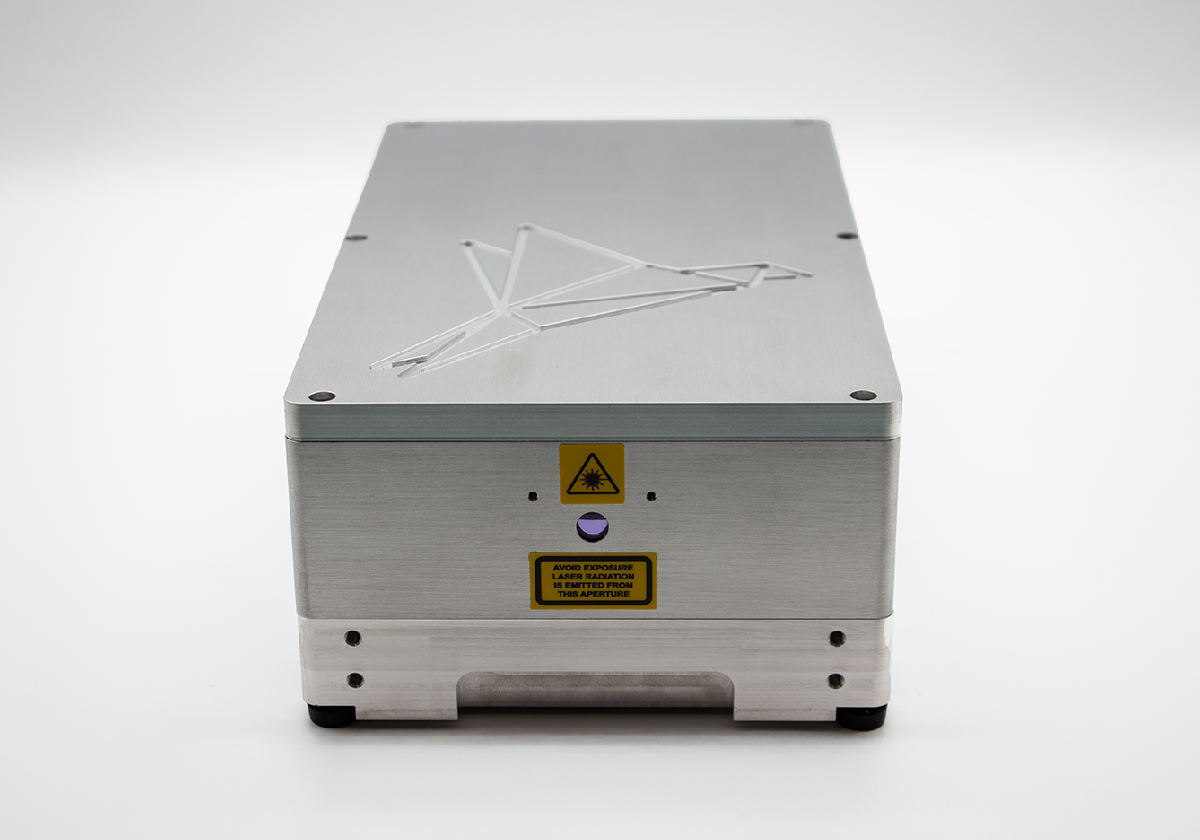

Skylark 320 NX

320 nm single frequency DPSS UV laser

349 nm

up to 400 mW

Skylark 349 NX

349 nm single frequency DPSS UV laser

Uniform intensity

≤ 0.3% RMS

Stable power

≤ 2.0%

Maintains consistent exposure over long runs, ensuring uniform feature formation and repeatable process outcomes across large substrates or batch operations.

Uniform beam

M² ≤ 1.2

Consistent wavelength

± 0.2 pm

Stable wavelength over extended periods, enabling precise, repeatable structure definition without recalibration or drift correction.

Single frequency DPSS lasers produce high resolution, high fidelity optical gratings

Interference lithography depends on phase-stable, spectrally pure UV light to create periodic structures with nanometer-scale precision. Skylark NX single-frequency DPSS lasers at 320 nm and 349 nm deliver the coherence, wavelength accuracy, and optical power needed for high-throughput, high-resolution fabrication. Their continuous-wave output ensures smooth, uniform energy delivery—free from pulse artefacts—enabling consistent exposure across large substrates.

From metasurface and AR waveguide mastering to photoalignment layer formation and optical coating patterning, Skylark lasers provide the stability and beam quality required to translate optical design fidelity directly into patterned structure quality.

Optical grating fabrication

Interference lithography using Skylark NX UV DPSS lasers provides the wavelength precision and coherence stability required for mastering high-performance optical gratings. Continuous-wave single frequency operation at 320 nm and 349 nm delivers sharp, uniform interference fringes for accurate control of line spacing and refractive index modulation. With narrow linewidths, high beam uniformity, and long-term power stability, Skylark NX UV DPSS lasers enable consistent, repeatable high fidelity gratings suitable for diffraction, spectroscopy, and waveguide applications.

Metasurface patterning

Metasurface fabrication demands sub-wavelength precision and phase control to define periodic features that shape the propagation of light. Skylark NX UV DPSS lasers at 320 nm and 349 nm offer the long coherence and spectral purity required for stable interference exposure across large fields. High optical power and a clean Gaussian beam enable deep, uniform photoresist modulation, supporting reproducible feature geometry and large-area patterning for dielectric or plasmonic metasurfaces.

AR waveguide fabrication

Creating uniform diffractive structures for augmented reality (AR) waveguides requires highly stable wavelength and fringe alignment. The Skylark NX DPSS platform provides precise wavelength accuracy (± 0.2 pm) and continuous-wave UV output for smooth, even exposure. This spectral consistency ensures accurate grating period control and repeatable coupling performance, helping manufacturers produce high-efficiency in- and out-coupling gratings for next-generation display optics.

Photoalignment layer (PAL) fabrication

Photoalignment processes for liquid crystal and polymer-based materials require highly uniform, stable UV illumination to induce consistent molecular orientation without mechanical contact. Skylark NX single-frequency DPSS lasers at 320 nm and 349 nm deliver continuous-wave output with excellent beam uniformity and low intensity noise (≤ 0.3 % RMS), providing precise energy control across coated surfaces. The combination of narrow linewidth, long coherence, and steady optical power ensures repeatable alignment layer quality and supports large-area, defect-free PAL fabrication for display, optical, and waveguide applications.

Liquid crystal polymer gratings (LCPGs)

Liquid Crystal Polymer Gratings (LCPGs) rely on highly uniform, phase-stable UV exposure to control molecular alignment and refractive index modulation. Skylark NX DPSS lasers at 320 nm and 349 nm provide continuous-wave, single-frequency light with exceptional spatial uniformity, delivering consistent exposure conditions for uniform LCPG formation in advanced optical and AR display systems.

REQUEST A QUOTE